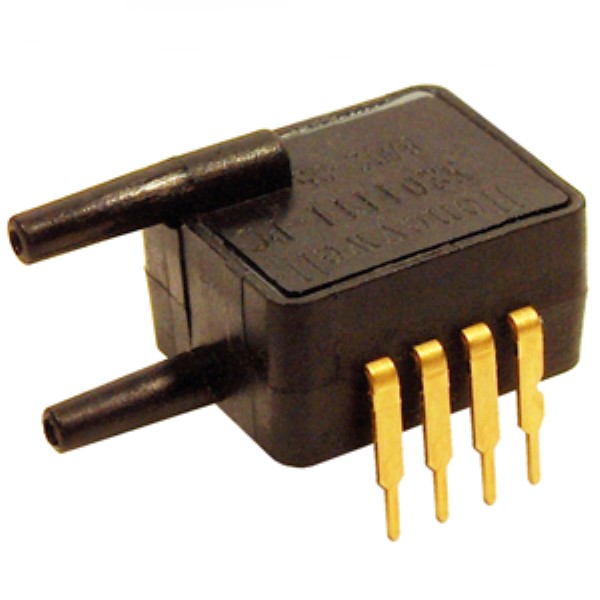

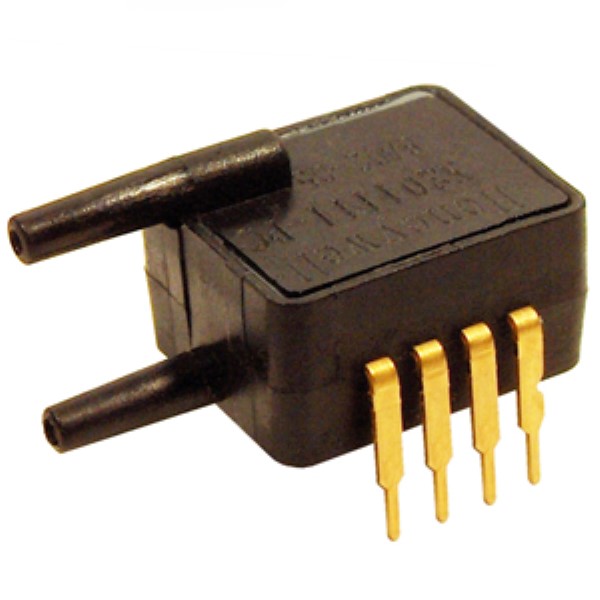

Pressure sensors convert physical pressure into an electrical signal so systems can monitor and control fluids, gases, and mechanical load. They're essential in manufacturing, test benches, medical devices, heating, ventilation, and air conditioning (HVAC), and embedded designs that need precise feedback.

Online Components offers reliable stock and U.S.-based shipping, giving purchasers confidence from spec to checkout. Our selection spans absolute, gauge, and differential pressure sensors with analog or digital outputs, surface-mount and through-hole packages, and wide operating ranges measured in pounds per square inch (PSI) or kilopascals (kPa). You'll also find helpful options such as temperature compensation and ingress protection (IP) ratings for demanding environments.

How to Choose the Right Pressure Sensors

Start with pressure type and range. Decide whether your design needs absolute (referenced to vacuum), gauge (referenced to ambient), or differential (difference between two ports), then select a range that fits normal operation with room for transients. Match the electrical interface to your system: analog voltage or current, or digital protocols such as Inter-Integrated Circuit (I²C) or Serial Peripheral Interface (SPI) for calibrated data and straightforward microcontroller integration.

Review mechanical and environmental needs: port style, package height, sealing approach, IP rating, temperature range, and media compatibility. Confirm the mounting style and footprint align with your assembly process and service plan.

Popular Applications for Pressure Sensors

Purchasers and engineers across production, maintenance, and research and development (R&D) shop this category when precision feedback is required and downtime is costly. Industrial automation relies on pressure sensors to regulate pneumatics, hydraulics, and process lines where stability and repeatability count.

Medical and life-science equipment uses compact sensors for respiratory support, dialysis, and fluid dispensing where resolution at low pressures is critical. HVAC and building systems depend on them for airflow, duct static, and refrigerant monitoring to maintain efficiency and safety.

Automotive and mobility projects apply them for intake, braking, and fluid systems. Embedded devices track barometric pressure for altitude, weather, or enclosure integrity.

Why Buy Pressure Sensors from Online Components?

Online Components pairs U.S.-based inventory with fast shipping, so in-stock parts move quickly to your bench or production line. Products are sourced through authorized channels to reduce counterfeit risk, and our customer service team responds with practical help when you need it. Our site streamlines purchasing: clear specs, parametric filters, and secure checkout keep the process tight from search to delivery.

Pressure Sensors: What You Need to Know

What's the difference between absolute, gauge, and differential pressure sensors?

Absolute sensors measure against a sealed vacuum reference, gauge sensors measure against ambient air, and differential sensors report the difference between two input ports. Pick the mode that fits how your system defines "zero" and what it's actually comparing.

How do I size the pressure range correctly?

Choose a range that covers normal operation with margin for start-up spikes and occasional surges. Too large a span wastes resolution; too small risks clipping and premature wear, so balance safety with the accuracy your control loop requires.

Analog or digital output: how should I decide?

Analog outputs (voltage or current loop) are simple, fast, and easy to read with basic hardware. Digital outputs over I²C or SPI deliver calibrated values, temperature compensation, and strong noise immunity when cable runs are longer or environments are harsh.

What environmental specs matter most?

Focus on temperature range, IP rating, and media compatibility. Confirm the sensor's wetted materials match your gas or fluid, and verify sealing and port style for your enclosure and tubing plan.

Are Microelectromechanical Systems (MEMS) pressure sensors suitable for industrial use?

Modern MEMS devices offer excellent stability and small footprints, and many are built for rugged settings. Check datasheets for vibration tolerance, drift, and calibration features to confirm fit for your duty cycle.

contact us

English

English

Chinese

Chinese

Italiano

Italiano

Portuguese

Portuguese

Deutschland

Deutschland

French

French

Russian

Russian

Japanese

Japanese

Turkish

Turkish

Korean

Korean

Spanish

Spanish