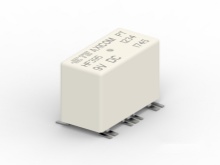

Electromechanical relays (EMRs) are electrically operated switches that control circuits across countless industries. Using an electromagnetic coil to open or close mechanical contacts, EMRs handle reliable switching of high or low-power circuits. These workhorses stay popular for good reason: they're durable, simple to operate, and provide solid isolation between control and load sides. Online Components keeps electromechanical relays in stock, offering U.S.-based shipping to give buyers confidence when timing matters. Since 1999, we've been an authorized distributor, focusing on supply reliability and fast, transparent delivery to keep projects on track.

Our selection of electromechanical relays runs deep, featuring leading brands such as TE Connectivity, Omron, Panasonic, and Schneider Electric. The catalog covers general-purpose, signal, power, automotive, and latching relays, providing customers with options to meet every technical requirement. You'll find relays with single-pole and multi-pole designs, as well as various coil voltages and contact ratings across the spectrum. The intuitive parametric search lets you filter by switching type, mounting style, size, and more. Engineers, original equipment manufacturers (OEMs), maintenance and repair operations (MROs), and procurement specialists choose Online Components for electromechanical relays, whether for new product development, urgent maintenance, or production line upgrades.

How to Choose the Right Electromechanical Relay

Selecting the right electromechanical relay for your application comes down to three key factors. First, match the relay's coil voltage and current ratings with your circuit requirements for proper operation. Next, determine how many poles and throws your design needs. Some systems function properly with basic single-pole, single-throw (SPST) relays, while others require more complex arrangements, such as double-pole, double-throw (DPDT) relays. Finally, verify the compatibility of your mounting options, such as through-hole, panel mount, or DIN rail, with your build or enclosure.

Popular Applications for Electromechanical Relays

Electromechanical relays form the backbone of automation, manufacturing, and infrastructure. Industrial control panels depend on EMRs for switching motors, pumps, and lighting safely and efficiently. Automotive systems use them for reliable switching of ignition, headlights, and power accessories. Heating, ventilation, and air conditioning (HVAC) controls depend on relays to manage compressors, fans, and valves. In communications and power distribution, EMRs protect sensitive circuits and deliver dependable signal routing. From equipment manufacturers to building automation, these relays keep modern systems running smoothly.

Why Buy Electromechanical Relays from Online Components?

Online Components delivers with deep, U.S.-based inventory, flat-rate global shipping, and verified supplier partnerships for complete peace of mind. Our user-friendly site, transparent pricing, and knowledgeable customer service team make ordering fast and frustration-free. Ready to secure reliable, in-stock relays with prompt delivery? Shop Online Components today and keep your projects moving forward.

Electromechanical Relays: What You Need to Know

What is the main advantage of using electromechanical relays over solid-state relays?

Electromechanical relays offer true galvanic isolation and can handle higher inrush currents, making them ideal for applications that require complete physical separation between the control side and the load circuit. They also perform better in harsh environmental conditions, such as high temperatures or electromagnetic interference.

How long do electromechanical relays typically last?

Quality EMRs can achieve hundreds of thousands or even millions of switching cycles, depending on load type and frequency of use. Their mechanical construction uses proven materials and methods. Mechanical life often exceeds 10 million operations, while electrical life typically ranges from 100,000 to over 1 million cycles under rated conditions.

Can EMRs be used for both alternating current (AC) and direct current (DC) switching?

Yes. Many electromechanical relays handle both AC and DC loads. Always consult product datasheets for voltage compatibility and ratings.

What are the key maintenance needs for electromechanical relays?

While EMRs require minimal maintenance, periodic inspections for contact wear or pitting are beneficial in high-use environments to prevent unplanned downtime. Regular visual inspections and testing of coil resistance and contact continuity can help identify potential issues before they lead to failure.

contact us

English

English

Chinese

Chinese

Italiano

Italiano

Portuguese

Portuguese

Deutschland

Deutschland

French

French

Russian

Russian

Japanese

Japanese

Turkish

Turkish

Korean

Korean

Spanish

Spanish