Newest Products

Fast track innovative solutions with our wide range of new and in-stock products from the world's most trusted brands.

Electronic resistors are essential components in nearly every modern electronic circuit, providing safe, precise control of electrical current and protecting sensitive devices from damage. The right resistor choice directly affects performance and reliability, whether you're managing high-volume manufacturing or working on a single prototype. Quality electronic component distributors offer extensive inventories, fast shipping, and authorized supplier sourcing to fill orders quickly with trusted parts.

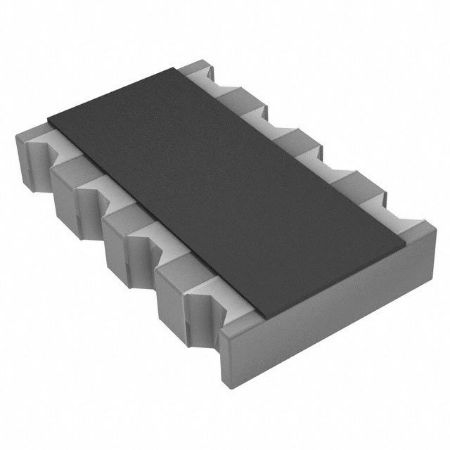

Our electronic resistor category features a comprehensive range, covering both fixed and variable types plus key specialty products. We stock major industry brands with resistors in countless resistance values, power ratings, and tolerance levels. You'll find surface-mount technology (SMT) chip resistors, through-hole carbon film resistors, high-precision metal film resistors, wirewound resistors for demanding power applications, and more. Filter by resistance (ohms), power rating (watts), tolerance percentage, or temperature coefficient to find exactly what your design needs. This selection works for production engineers, maintenance professionals, electronics designers, and hobbyists.

Selecting the best electronic resistor starts with reviewing your circuit's requirements. Determine the correct resistance value in ohms to match your electrical needs. A mismatch can cause circuit instability or component failure. Check the power rating in watts to verify the resistor can safely dissipate heat under normal operating conditions. Consider whether SMT or through-hole mounting fits your process. Applications requiring precise voltage control or low noise benefit from resistors with tighter tolerance and stable temperature coefficients. These specifications affect both product longevity and system performance.

Electronic resistors power countless applications. Consumer electronics manufacturers use them in mobile phones, tablets, and home entertainment systems. The automotive industry relies on resistors for safety systems, lighting modules, and engine control units. Industrial automation depends on resistors for motor control, sensor protection, and signal conditioning in factory environments. Medical equipment designers choose high-precision resistors for patient monitors and diagnostic devices, where accuracy and safety matter most. Educational labs and makerspaces stock resistors for training kits, circuit experiments, and prototypes. Having the right part available can make the difference between a smooth launch and expensive delays.

Online Components provides extensive inventories, fast shipping, and authorized supply chains. Major distributors like Online Components give immediate access to hundreds of thousands of resistor part numbers, ready to ship same day in most cases. Every product listing includes detailed technical information and real-time stock status, making selection and ordering straightforward. Our experienced customer service teams handle questions and sourcing needs, creating a smooth purchasing process. For electronics professionals who value speed, reliability, and verified authenticity, established distributors are the smart choice. Purchase your electronic resistors from reputable distributors today and keep your projects moving forward.

Resistors are available in several core types, including fixed, variable, wire-wound, thick-film, and thin-film. Fixed resistors maintain a constant resistance, whereas variable types, such as potentiometers or rheostats, allow for adjustable resistance. Wirewound resistors are ideal for high-power applications due to their durability and accuracy. Thin film resistors offer low noise and high precision, whereas thick film resistors are commonly used in less sensitive, cost-conscious designs. The best type depends on performance, stability, and environmental requirements.

Tolerance defines the maximum variation in a resistor's resistance from its labeled value. Common tolerances include ±0.1%, ±1%, and ±5%, with lower values indicating higher precision. High-precision circuits, such as analog measurement systems, require tighter tolerances to ensure accuracy. In contrast, digital or power supply applications may function reliably with broader tolerance ranges. Evaluate your circuit's sensitivity to resistance variation before selecting a tolerance level.

The power rating indicates the amount of heat a resistor can safely dissipate, expressed in watts. If a resistor dissipates more power than it is designed to handle, it can overheat, drift in value, or fail. To ensure reliability, choose a resistor with a power rating of at least twice the expected load. In high-current or thermally constrained designs, derating may also be necessary. Always verify environmental conditions to ensure you do not exceed rated performance.

Yes, high-power resistors rated at 5 watts, 10 watts, or higher handle greater heat and current loads. They're commonly used in power supplies, amplifiers, and industrial equipment.

At high frequencies, resistors can exhibit parasitic inductance and capacitance, which affect their performance. Wirewound resistors, for example, are generally unsuitable due to their inherent inductive properties. Thin film resistors are preferred in RF or high-speed digital circuits because of their stability and low parasitic effects. In sensitive signal paths, it's essential to select components specifically designed for high-frequency applications. Always review frequency response data when selecting resistors for such applications.

The temperature coefficient (TC) measures the change in resistance with temperature, expressed in parts per million per degree Celsius (ppm/°C). A low TC (e.g., ±25 ppm/°C) is crucial for applications requiring consistent resistance across varying thermal conditions. Higher TC values can lead to significant resistance drift in environments with fluctuating temperatures. This can affect performance in precision analog, timing, or sensor circuits. Select resistors with appropriate temperature coefficient (TC) ratings based on the operating temperature ranges and stability requirements.

SMT resistors are compact and designed for automated assembly on printed circuit boards (PCBs), while through-hole resistors have leads for manual or wave soldering. Your assembly process and board design will guide this choice.

Absolutely. Resistors function the same way in AC and DC circuits, reliably controlling current and dividing voltage.

Electrical and wire connectors form the essential links in any electrical or electronic system, providing safe, dependable pathways for current and signal between devices, circuits, and assemblies. These connectors serve as the backbone in sectors from industrial automation and automotive manufacturing to telecommunications, consumer electronics, renewable energy, and beyond. At Online Components, engineers, purchasers, and manufacturers rely on our deep, consistently stocked U.S.-based inventory of electrical and wire connectors. With fast shipping and genuine, authorized parts, you can count on our platform to keep your projects moving without last-minute shortages or substitutes.

Our selection covers a broad spectrum of electrical and wire connectors from top brands like TE Connectivity, Amphenol, and Phoenix Contact. You'll find terminal blocks, circular connectors, rectangular connectors, insulation displacement connectors (IDC), crimp connectors, and both wire-to-board and wire-to-wire types. Critical specifications like current rating, voltage, contact material, housing type, environmental protection, and termination style are easy to filter and compare.

Choosing the right electrical and wire connector starts with knowing your application's requirements. Evaluate the electrical characteristics first: current and voltage ratings must meet or exceed your system's needs for safety and reliability. Next, think about the operating environment. Applications subject to vibration, moisture, dust, or temperature swings demand connectors with strong environmental sealing or locking features. Finally, look at assembly and maintenance needs. Crimp connectors offer vibration resistance and permanence, while screw terminal and IDC types support easier rework and field adjustments.

Electrical and wire connectors are critical across multiple industries. Automotive engineers depend on reliable, vibration-resistant connectors for engine management, safety systems, and advanced electronics. Industrial automation relies on durable, easy-to-service connectors for machine controls and sensors. Consumer electronics require compact connectors to save space and maintain signal quality. Data centers need precision connectors for high-speed, low-loss signal transfer. Renewable energy installations call for weather-resistant, high-current connectors.

Online Components provides a massive, U.S.-based inventory of genuine electrical and wire connectors, all sourced directly from authorized suppliers. Our focus on availability means thousands of part numbers in stock and ready for immediate shipping. Responsive customer service, competitive pricing, and streamlined online ordering make procurement simple and stress-free. With supplier authentication and deep category expertise, you can shop with confidence, knowing your connectors will arrive quickly, ready for immediate use.

Most connectors use strong plastics for insulation and durability, combined with copper alloys or brass contacts for superior conductivity and mechanical strength. Advanced materials are increasingly important for extreme temperature environments.

Always choose a connector with a current rating equal to or higher than your application's maximum current. Include a safety margin for long-term reliability, especially in demanding environments.

Crimp connectors form permanent, vibration-resistant bonds using specialized tools. IDC connectors allow rapid connections to ribbon cables without stripping insulation. Screw terminal connectors clamp wires securely for quick changes or field service.

No, only connectors with explicit environmental sealing or Ingress Protection (IP) ratings are suitable for outdoor or industrial use. IP ratings rate resistance against dust and liquid intrusion. For harsh environments, connectors should be dust-tight with water ingress protection, typically requiring IP68 or higher ratings.

Some connectors with screw or snap-in designs are reusable. Crimp and IDC connectors are generally single-use since reusing may compromise connection quality and safety.

Electronic relays are essential components in electrical systems, functioning as electrically controlled switches that manage circuits with consistent reliability. By bridging low-power control signals to high-power loads, relays enable safe, precise, and efficient switching across industries. Shop electronic relays at Online Components for dependable U.S.-based inventory, rapid shipping, and guaranteed in-stock options. Customers choose us for peace of mind, knowing they receive authorized components and straightforward, hassle-free service.

Our electronic relay selection encompasses industry-leading brands such as TE Connectivity, Omron, and Panasonic. Online Components stocks a wide range of electromechanical relays, solid-state relays (SSRs), reed relays, time delay relays, latching relays, and miniature relays. Each type suits different voltages, coil types, switching currents, and mounting configurations. Users can filter products by coil voltage, contact arrangement, switching capacity, or package style to find the best fit for any project. Do you need board-level surface mount devices or heavy-duty panel-mount solutions? We make it easy to find the correct electronic relay for your application. Design engineers, manufacturing purchasers, field maintenance teams, and electronics hobbyists rely on our broad inventory to keep projects and production schedules on track.

Choosing the right electronic relay comes down to several key factors. First, evaluate your load requirements: the voltage and current you need to switch. Using a relay outside its specified range risks performance issues or damage. Next, decide between electromechanical relays and SSRs. Electromechanical relays use physical contacts for switching, offering reliable isolation and audible operation. Solid-state relays use semiconductor technology for faster, quieter, and longer-lasting operation with no moving parts. Consider your operating environment, too. Temperature, humidity, and vibration can significantly impact whether you require a sealed or ruggedized relay for optimal longevity and safety. Careful matching of relay specifications to your project's needs ensures lasting performance and reliability.

Electronic relays play an essential role in several key industries. Industrial automation uses relays to manage motors, pumps, lights, and machine safety interlocks. Automotive systems rely on them for engine control, lighting, and accessory circuits. Building automation employs relays to manage HVAC controls, lighting automation, and access systems. Consumer electronics, ranging from smart home devices to appliances, often incorporate miniature relays for switching and isolation purposes. Critical infrastructure sectors, such as telecommunications and renewable energy, utilize relays to control and protect their equipment.

Source electronic relays from Online Components and gain access to U.S.-based inventory, featuring hundreds of thousands of stock-keeping units (SKUs) available for immediate shipping. Every relay is sourced directly from authorized suppliers, ensuring authenticity and optimal performance. You'll benefit from flat-rate global shipping, quick and knowledgeable customer support, and a seamless online shopping experience. Real-time inventory and transparent pricing eliminate surprises, making it simple to keep your supply chain moving. Ready to upgrade your sourcing experience? Explore our selection of electronic relays and place your order today.

Relays can be categorized into three main types: electromechanical relays (EMRs), solid-state relays (SSRs), and hybrid types. EMRs utilize physical contacts and are well-suited for applications that require isolation and high-load switching. SSRs utilize semiconductor components to switch loads silently, eliminating mechanical wear. Hybrid relays combine both technologies to deliver improved performance for specific applications. Your best choice depends on factors like switching speed, lifetime requirements, noise tolerance, and load type.

The coil voltage rating must match the voltage of your circuit's control signal. Common options include 5V, 12V, or 24V DC, as well as various AC voltages. Using too low a voltage may prevent the relay from activating, while too high a voltage can cause overheating and damage. Factor in the relay's pull-in and drop-out voltages when designing your circuit. Ensure your circuit can supply sufficient current to energize the coil reliably. Always consult the datasheet for exact coil specifications.

Usually, open (NO) contacts stay open when the relay is de-energized and close when activated, allowing current to flow. Closed (NC) contacts work in reverse. They remain closed when the relay is off and open when energized. Select 'NO' or 'NC' based on whether your circuit should be powered by default or only when the relay is activated. Some relays offer multiple contact configurations (such as SPDT or DPDT) for more complex switching requirements. Ensure the contact type matches your circuit's intended behavior.

The contact rating specifies the maximum voltage and current that the relay's contacts can safely switch. Exceeding this rating can cause contact arcing, overheating, or premature failure. Ratings typically cover both resistive and inductive loads. Inductive loads, such as motors, may require derating due to the higher inrush currents they generate. Match the contact rating to your load type and include a safety margin for reliable operation. Review both AC and DC ratings, as they often differ significantly.

Electromechanical relays aren't ideal for high-speed or high-frequency switching due to mechanical limitations and contact bounce. Solid-state relays work better for these applications, offering faster response times and longer service life. For rapid cycling or pulse switching, verify the relay's switching speed and recommended duty cycle. In some cases, MOSFET or transistor-based switching solutions may be more suitable. Always select relays rated for your design's switching frequency and operational requirements.

Yes, but check each relay's ratings first. Some work specifically with AC loads, some with DC, and others can switch between. Refer to the product datasheet for compatibility information with your application.

Absolutely. Relays are often chosen to control high-power devices such as motors, heaters, and large lighting systems. Choose a relay with ratings that meet or exceed your switching current and voltage needs for safe and reliable operation.

Electromechanical components bridge the gap between electrical signals and mechanical action, making them essential building blocks for modern industry, automation, and device design. From relays to switches, solenoids, and panel controls, these parts are the hands and feet of electronic systems, turning instructions into action with reliability and precision. Online Components is a trusted source for electromechanical components, earning a reputation for reliable, in-stock inventory and fast, U.S.-based shipping.

Browse our extensive selection and you'll find electromechanical components from leading brands, including Omron, TE Connectivity, C&K, Honeywell, and Panasonic. Whether you're searching for toggle or rocker switches, rotary encoders, motors or solenoids, our line card spans the full range of form factors, ratings, and mounting options. Customers can sort by voltage, current, actuation force, size, environmental sealing, and more. Engineers, purchasers, and repair technicians rely on our depth of selection to keep assemblies running, production lines moving, and prototypes on schedule.

Selecting the right electromechanical component involves balancing several key factors. First, identify the operating environment: temperature, humidity, and potential exposure to dust or moisture will influence your need for ruggedized or sealed components. Next, verify electrical ratings. Match voltage, current, and switching capacity to your system's demands to prevent failures and maximize lifespan. Finally, think through mechanical factors such as actuation method, size, and mounting style. This guarantees compatibility with your existing design or enclosure. Take the time to cross-reference datasheets and specifications to make sure your choice aligns with both performance needs and physical fit.

Electromechanical components are everywhere where electrical control needs to interface with the physical world. In industrial automation, relays and contactors handle power switching for motors, pumps, and valves, while limit switches provide feedback on machine position or safety status.

Building management systems rely on a variety of push-button switches, key locks, and relays to control lighting, security, and HVAC. Medical devices utilize precision switches and sensors to ensure user safety and equipment reliability, ranging from surgical robots to diagnostic equipment. Automotive systems rely on rugged relays, panel switches, and actuators for a wide range of functions, including headlight control, power windows, and advanced driver-assist features.

Online Components sets itself apart with extensive inventory, verified supplier partnerships, and rapid fulfillment you can trust. Every part in our catalog is sourced directly from authorized suppliers so that you can order with confidence. Our streamlined ordering system and transparent stock status keep your workflow smooth, while responsive customer service is always ready to assist if questions arise. Need your order fast? Most in-stock parts ship the same day from our U.S. warehouses. When you're ready to move from selection to purchase, Online Components makes the process seamless.

Relays, switches (toggle, rocker, pushbutton), solenoids, contactors, rotary encoders, and panel controls top the list. Each serves a different purpose, so think through your application's electrical and mechanical requirements.

Refer to the datasheet for the maximum voltage and current ratings, and select a component with ratings that exceed your system's maximum loads. Overspecifying slightly can provide extra margin for reliability.

While industrial components may offer enhanced durability, verify that they meet certifications or comply with consumer device standards before use. Size and price may also influence your decision.

For outdoor or harsh environments, look for IP-rated (Ingress Protection) switches with ratings of IP65 or higher to protect against moisture, dust, and debris. IP65 protects against water jets, while IP67 offers protection against temporary water immersion up to one meter deep.

Sensors and transducers convert physical inputs (pressure, temperature, magnetism, and sound) into electrical signals that systems can process. This category covers the basics: general sensors, magnetic sensors, pressure sensors, temperature sensors, audio components, and related accessories for integration and maintenance. These parts provide feedback, protection, and control in production lines and devices where accuracy and repeatability count. Online Components backs this work with reliable stock, U.S.-based shipping, and authorized sourcing.

Start with the variable and range you need to measure, then match it to the right device type: magnetic sensors for position or speed, pressure sensors for absolute or differential monitoring, temperature sensors for thermal control, and audio components for sound transduction.

Pin down output and interface next. Will you use analog voltage or current, or a digital bus such as Inter-Integrated Circuit (I²C), Serial Peripheral Interface (SPI), or Universal Asynchronous Receiver-Transmitter (UART) that fits your controller and bandwidth needs?

Confirm electrical and mechanical fit: supply voltage, package style, port geometry for pressure devices, and accessory requirements like cables or mounting hardware. Check environmental limits, too. Operating temperature, humidity tolerance, and Ingress Protection (IP) ratings all come into play when dust or moisture exposure is expected.

Procurement teams, test engineers, and design engineers pick these parts for new designs, line maintenance, and field retrofits. Magnetic sensors provide position feedback in factory automation while pressure sensors safeguard pneumatics and hydraulics.

Heating, ventilation, and air conditioning (HVAC) systems use temperature sensors for control loops and energy management. Building systems rely on general sensors for occupancy and status monitoring.

Medical and lab equipment depend on pressure and temperature sensors to stabilize pumps and maintain process conditions. Consumer and embedded products use audio components for signaling and detection tasks where acoustic cues count.

Online Components combines U.S.-based inventory, fast shipping, and authenticated supply to reduce risk and shorten lead times. The sensors and transducers selection is broad, with real-time availability and parametric filtering that speeds up part selection. Competitive screen pricing and responsive customer service make sourcing simpler.

Tie these specs to the decision or threshold in your system. Small changes that trigger control actions demand tighter accuracy and fine resolution. Where you only need coarse thresholds, a wider spec can reduce cost and complexity while maintaining reliability.

Analog outputs are simple and fast to read with an Analog-to-Digital Converter (ADC). Digital interfaces such as I²C, SPI, or UART add features like on-sensor filtering and diagnostics. Choose based on available microcontroller resources, noise tolerance, wiring length, and required sample rate.

Confirm operating temperature range, humidity exposure, and any needed IP protection. For pressure devices, verify media compatibility and port type. For audio components, review mounting and acoustic path constraints. Check calibration method, drift over time, and whether field calibration is supported to maintain long-term stability.

Yes. Proper cables, seals, and mounting accessories improve signal integrity, reduce mechanical stress, and preserve environmental ratings. Matching accessories to the sensor or transducer helps preserve accuracy and extend service life.