Before we tackle this question, we should begin with several definitions. These days you often see hardware parts or components or even systems being marketed as MIL-SPEC, MIL-STD, or even MILITARY GRADE. Other than implying a sense of ruggedness, just what do these terms mean?

In common use, MIL-SPEC and MIL-STD have become somewhat interchangeable, and somewhat confusing. They both generally mean that a component meets the requirements set by the U.S. Department of Defense for sourcing, fabrication, material, quality, and supply.

MILITARY GRADE is simply a marketing term meant to help sell products on the open market, and has no connection to either standards or specifications. As a product adjective, however, “military grade” can now be found attached to a wide range of products, from consumer goods to business and industrial products. Let the buyer beware!

For our purposes, however, a military SPECIFICATION refers to a Department of Defense document that covers the physical properties of a component as well as how it operates. A military STANDARD refers to a Department of Defense document covering how a component is made and the materials that are used to manufacture it. For example, a specification might stipulate the particular type of wire to be used in a circuit, and a standard would indicate how to insert the wire in the circuit and how to test it.

The current interchangeable use of the MIL-SPEC and MIL-STD terms is just a quick way to signify that a particular component meets the requirements of a specific Military Standard (MIL-STD) or Military Specification (MIL-SPEC). Some other terms you may see include MIL-DTL, which stands for Detail Specification; or MIL-PRF, which stands for Performance Specification.

The U.S. Department of Defense, through the Defense Standardization Program (DSP), has attempted since 1945 to standardize its supply sourcing programs and keep the amount of individual component part options under control by stipulating specific design details. This makes sense when you are dealing with the logistics of supplying an organization with bases around the globe. This standardization allows for consistent part commonality, compatibility, reliability, and interoperability between systems. It also allows for efficiencies in maintenance and repair, and it also saves money.

Organizing and controlling part sourcing through this process is a huge undertaking, as might be expected for any organization as large as the U.S. military. Indeed, the DSP notes that despite its ongoing efforts, there are currently over 28,000 active military documents covering specifications and standards in use covering thousands of products. Not all of these products are actively marketed as MIL-SPEC, but many are.

A Word About Testing

In addition to meeting the technical details of Department of Defense specifications and standards, a part, in order to be labeled as MIL-SPEC, must undergo rigorous testing to certify its operation under severe conditions. MIL-SPEC designated parts to be used in a military program are required to be tested and certified by the Defense Logistics Agency (DLA), and the production facility in which they are manufactured must also be qualified.

This adds an additional layer of assurance that the parts will work as needed, and it adds additional weight to the importance of the MIL-SPEC classification.

MIL-SPEC vs Regular Components

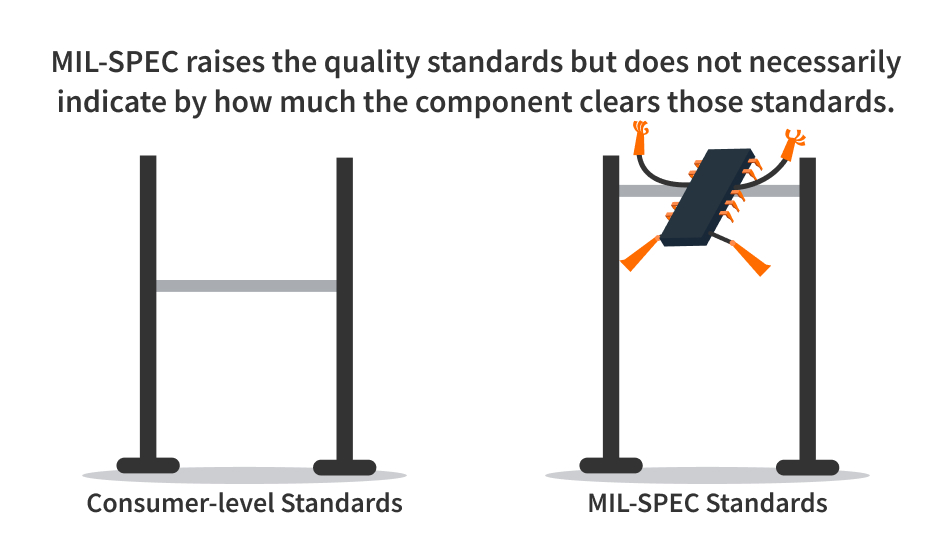

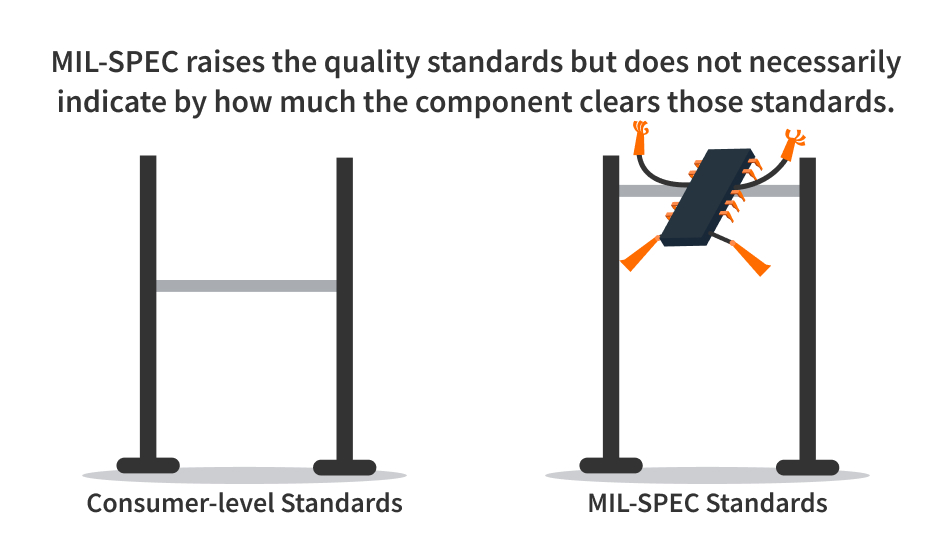

So, after that forward, and getting back to our initial question, the quick answer is that, yes, products designated as MIL-SPEC are probably better than “regular” products for their intended applications. Components supplied to the military must meet defense department standards or specifications. They must be of high quality, capable of performance under extreme conditions, and must be interchangeable with parts from other suppliers of the same product.

To say that a product is MIL-SPEC or MIL-STD generally implies that it is designed, built, and tested to a higher level of performance specifications than a “regular” product. It may also imply that the product will be more reliable, will last longer, and may also cost more. If the system you are designing requires adherence to a military specification or standard, then you must source MIL-SPEC parts.

Our friends at Circuitbread.com offer some amazing explanations about the common questions an electrical engineer would have, which include topics ranging from certifications required for electronic appliances to the challenges faced in scaling EV technology. They have also talked about MIL-SPEC components, and we highly recommend you to check out what they have to say about this: What are MIL-SPEC or Military Grade Components?

contact us:

EN

EN

English

English

Chinese

Chinese

Italiano

Italiano

Portuguese

Portuguese

Deutschland

Deutschland

French

French

Russian

Russian

Japanese

Japanese

Turkish

Turkish

Korean

Korean

Spanish

Spanish

my account & orders

my account & orders